ADS Laser

Industry

Manufacturing

Features

Materials

Flexible Metals

Flexible Metals Wood

Wood Flexible Plastic

Flexible Plastic Cardboard

Cardboard Paper

Paper

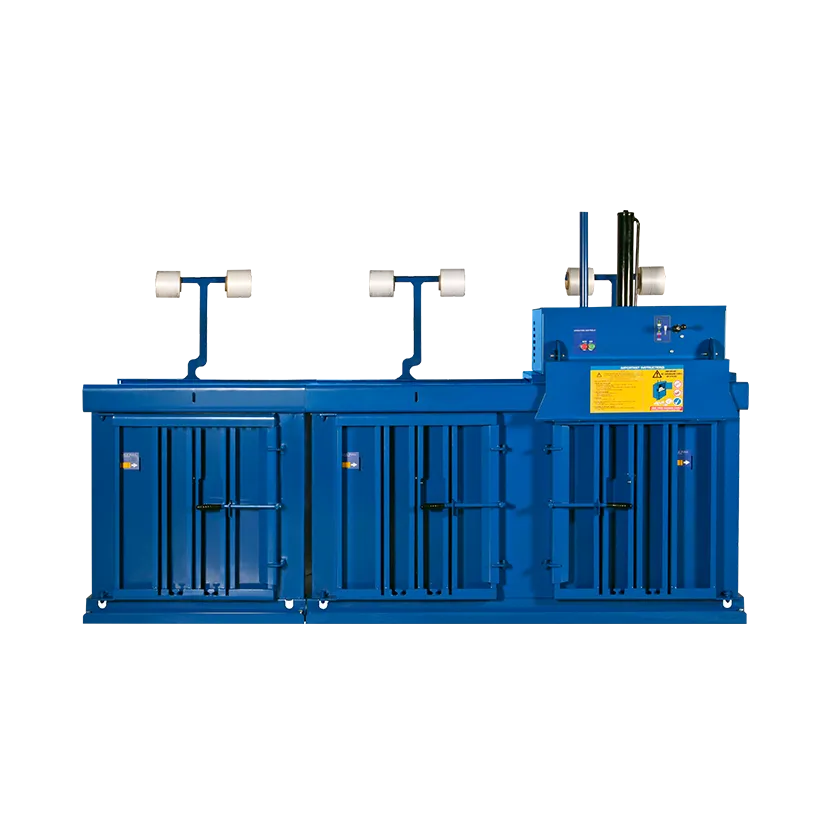

ADS Laser, a manufacturer specializing in parts and assemblies from metal, is dedicated to minimizing its environmental impact. The introduction of a waste management baler, the LFA 51 T, represents a significant step towards achieving this goal by enhancing recycling efforts for cardboard, paper and plastics. This case study examines how this investment aligns with ADS Laser’s sustainability objectives.

ADS Laser operates in the manufacturing sector, producing high-quality metal parts and assemblies for various applications. The company generates a range of waste materials, including metals, wood, plastics, cardboard, and paper. While these materials are often recycled or reused for packaging, ADS Laser recognised the need to improve its waste management practices further.

To align with its sustainability goals, ADS Laser aims to maximize recycling rates and minimize landfill waste, as outlined in its Objectives Register and ISO 14001 accreditation. The existing waste management processes were inefficient, prompting discussions on investing in waste machinery.

The decision to invest in a waste management baler was driven by key priorities: efficiency, ease of use, and cost reduction. After evaluating several options, ADS Laser chose to partner with Landfill Alternatives, which provided a comprehensive package that met the company’s requirements.

The LFA 51 T baler is expected to simplify the separation and processing of recyclable materials, contributing significantly to the company’s sustainability goals.

Since implementing the LFA 51 T baler, ADS Laser has observed several improvements:

1. Increased Awareness: Employees are now more proactive in separating recyclable materials.

2. Enhanced Cleanliness: A tidier shop floor has resulted in a safer working environment, with fewer combustible materials present.

3. Future Financial Benefits: Although the first loads of recycled materials have not yet been delivered, the potential financial rewards from recycling cardboard, plastic, and paper are anticipated. Although the reduction in wheelie bins have already proved the installation of the baler to be financially beneficial already.

ADS Laser are now recycling approximately 90% of all materials used on-site, marking a significant achievement in their waste management efforts. This accomplishment not only supports the company’s sustainability objectives but also demonstrates a commitment to responsible manufacturing practices.

The LFA 51 T baler plays an integral role in streamlining waste processing and improving overall operational efficiency and has contributed to substantial environmental benefits.

ADS Laser encourages other organizations to consider similar investments, emphasizing the long-term benefits of efficient waste management and recycling practices.

“ADS are going the extra mile to reduce its carbon footprint and the introduction of the Waste Management Baler to separate Cardboard, Paper and Plastic, is the next stage on this journey.” Anthony Littlejohns, Compliance Manager

The LFA 51 T baler has proven to be a valuable asset for ADS Laser, driving improvements in waste management efficiency and sustainability. As the company continues to pursue its environmental goals, the baler will play a crucial role in optimizing operations and reducing its carbon footprint.

A baler was high on ADS’s lists of priorities. We looked at 3 or 4 companies who offered this and were happy with the package that Landfill Alternatives offered.

Anthony Littlejohns, Compliance Manager

Compliance Manager

Case Study

Featured Products

Happy Clients

Related Case Studies

Retail

RetailWollaston BMW

Wollaston Motors, who are the BMW dealership in Northampton, have an APB 20 BL fully sealed portable compactor.

- Features

LFA 151

LFA 151

Free Waste Management Audit

Get a zero obligation, onsite waste audit to identify potential savings, optimise efficiency and cut costs.

Arrange Free Audit